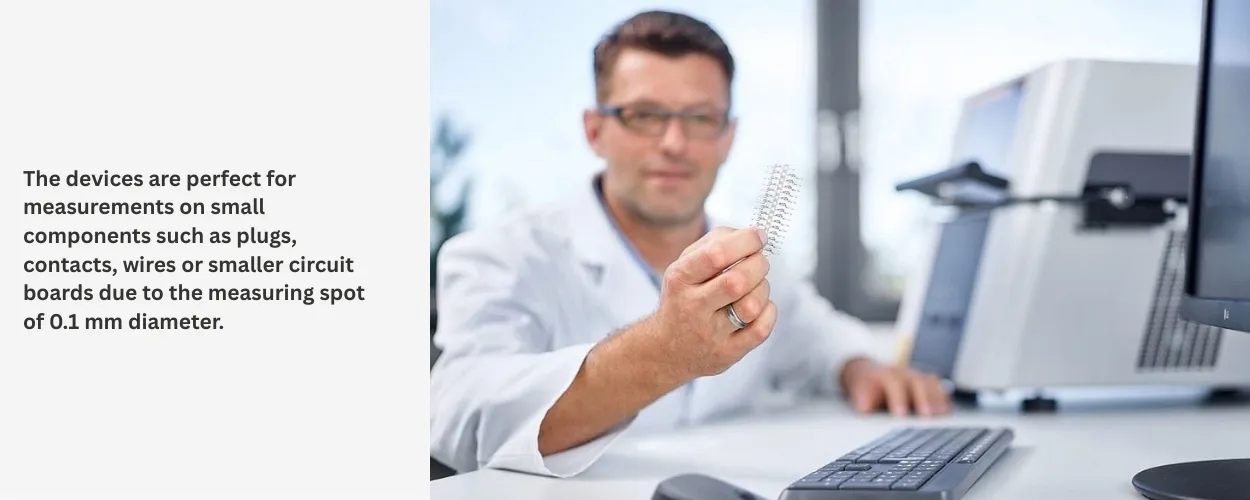

Entry-level XRF analyzer designed for fast, non destructive coating thickness measurement and material analysis. Ideal for precise testing of small components such as plugs, contacts, wires, and compact PCBs, as well as for determining metal content in electroplating baths and analyzing simple alloy layers.

PC-detector with largest

measuring window on the market

Smallest measuring spot

with 0,1 mm

Fix or 4-fold exchangeable apertures

Fix or 3-fold changeable filters

X-ray Fluorescence Analysis Made Simple

The FISCHERSCOPE X-RAY XULM / XUL series offers compact and highly flexible XRF instruments designed for non destructive coating thickness measurement and material composition analysis. Equipped with an integrated proportional counter tube detector, these systems enable rapid measurements even at greater working distances and on components with complex geometries, while still maintaining small measurement spot sizes. Thanks to these capabilities and a range of practical features, the XULM / XUL models are essential for quality assurance, incoming inspection, and process control particularly within electroplating environments.

Excellent Visibility

One of the largest measurement windows available.

Quick-Measure Handling

Samples can be positioned and measured in just a few simple steps.

Suitable for Large Samples

C-slot hood design accommodates flat and oversized components.

Easy Commissioning

Setup is straightforward and ready to use in no time.

Cost-Effective Performance

Provides an ideal balance between price and capability.

Multiple Measurement Points

Enables measurements across the entire surface, even on wide samples.

Key Features

- #Microfocus X-ray tube

- Individual measurements

- Fixed or 3-fold changeable filters

- Smallest measuring spot approx. Ø 0.1 mm

- Proportional counter tube detector for short measuring times

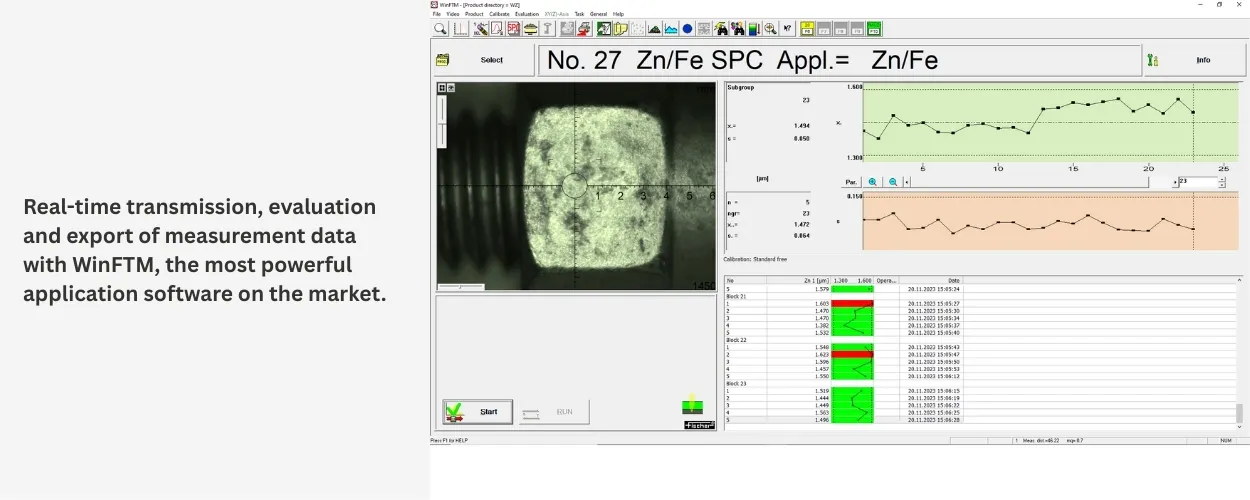

- Live image of the measuring point

- Up to 170 mm possible height of samples

- Fixed or 4-fold changeable apertures

- Type approved full protection device

Application examples

- Electroplating applications such as zinc on iron or zinc–nickel on iron for corrosion-resistant mass-produced parts

- Analysis of metal content in electroplating baths

- Decorative Cr/Ni/Cu coatings on ABS components

- Coating inspection for connectors and contacts in electronics

- Manual measurement of PCB coatings

- Precision measurements in the watch and jewelry industry

FISCHERSCOPE X-RAY XULM / XUL – Introduction

Helmut Fischer

Helmut Fischer

Global Leader in High-Precision Measurement Technology

Helmut Fischer is an international leader in precision measurement technology. The company has more than sixty years of experience in developing reliable and non destructive solutions for material analysis. Its instruments are trusted by laboratories, manufacturers, and quality control teams around the world. As a result, Fischer has built a strong reputation for accuracy, consistency, and long-term performance.Advanced Systems for Material and Coating Analysis

Fischer instruments are engineered to deliver accurate and repeatable results. They support coating thickness measurement, multi-layer inspection, and detailed material composition analysis. Because of their precision, these systems are widely used in electronics manufacturing, metal finishing, aerospace components, automotive parts, jewelry authentication, and research laboratories.

In addition, Fischer solutions offer fast operation and stable results with minimal setup time. This makes them suitable for both routine inspection tasks and advanced analytical workflows.

Where Fischer Instruments Deliver the Highest Value

Fischer technology provides strong value in environments that require dependable measurement quality. Its advanced fluorescence and material analysis systems help detect coating thickness, alloy composition, and trace elements with confidence. These capabilities are especially useful in PCB production, plating lines, aerospace and automotive inspection, precious metal verification, and laboratory testing.

Furthermore, the instruments support high-volume production as well as detailed research, giving users flexibility across different applications.

Intelligent Design, Stable Performance, Proven Reliability

Every Fischer system combines modern software, high-performance detectors, and a stable mechanical design. This combination ensures consistent measurements, clear reporting, and long-term calibration stability. Users benefit from an intuitive experience while maintaining precise control over their analysis tasks.

Helmut Fischer continues to advance measurement technology through innovation and reliability.

For official information, visit: www.helmut-fischer.com

Helmut Fischer is a world leader in measurement technology. Its portfolio includes XRF instruments, tactile measuring devices, automation solutions, and nanoindentation systems designed for unmatched precision and innovation.