-

Handheld, desktop, inline: the XAN®500 X-ray fluorescence instrument is Fischer’s most versatile yet. It can be used as a handheld device, as a fully enclosed desktop unit or integrated directly into production lines. Equipped with a tablet computer, the XAN500 also utilizes the time-proven WinFTM® software. Coating thickness measurements with WinFTM is based on the fundamental parameter analysis. This makes it possible to measure without prior calibration – that is, standard-free. https://www.youtube.com/watch?v=rUdDK9RjtwA

Handheld, desktop, inline: the XAN®500 X-ray fluorescence instrument is Fischer’s most versatile yet. It can be used as a handheld device, as a fully enclosed desktop unit or integrated directly into production lines. Equipped with a tablet computer, the XAN500 also utilizes the time-proven WinFTM® software. Coating thickness measurements with WinFTM is based on the fundamental parameter analysis. This makes it possible to measure without prior calibration – that is, standard-free. https://www.youtube.com/watch?v=rUdDK9RjtwA -

Handheld, desktop, inline: the XAN®500 X-ray fluorescence instrument is Fischer’s most versatile yet. It can be used as a handheld device, as a fully enclosed desktop unit or integrated directly into production lines. Equipped with a tablet computer, the XAN500 also utilizes the time-proven WinFTM® software. Coating thickness measurements with WinFTM is based on the fundamental parameter analysis. This makes it possible to measure without prior calibration – that is, standard-free. https://www.youtube.com/watch?v=rUdDK9RjtwA

Handheld, desktop, inline: the XAN®500 X-ray fluorescence instrument is Fischer’s most versatile yet. It can be used as a handheld device, as a fully enclosed desktop unit or integrated directly into production lines. Equipped with a tablet computer, the XAN500 also utilizes the time-proven WinFTM® software. Coating thickness measurements with WinFTM is based on the fundamental parameter analysis. This makes it possible to measure without prior calibration – that is, standard-free. https://www.youtube.com/watch?v=rUdDK9RjtwA -

As modular units, the instruments of the X-RAY 5000 range can be easily integrated into manufacturing lines. For example, when coatings on large-surface substrates such as tin sheets must be measured, X-RAY 5000 is the ideal solution. Depending on the base and coating materials, the X-ray source, detector and primary filter can be customized to the customer's needs. https://youtu.be/2JyWAduAX9w

As modular units, the instruments of the X-RAY 5000 range can be easily integrated into manufacturing lines. For example, when coatings on large-surface substrates such as tin sheets must be measured, X-RAY 5000 is the ideal solution. Depending on the base and coating materials, the X-ray source, detector and primary filter can be customized to the customer's needs. https://youtu.be/2JyWAduAX9w -

The FISCHERSCOPE X-RAY 4000 is specially designed for coating thickness measurement and material analysis during strip electroplating processes. This measurement system has already been installed over 300 times in electroplating plants of diverse sizes. Because of the fast mechanisms for moving the measurement head, readings can be taken at various points on the product to be measured. The instrument's modular design enables targeted selection of the optimal X-ray source and the ideal detector to meet your specific requirements. https://youtu.be/2JyWAduAX9w

The FISCHERSCOPE X-RAY 4000 is specially designed for coating thickness measurement and material analysis during strip electroplating processes. This measurement system has already been installed over 300 times in electroplating plants of diverse sizes. Because of the fast mechanisms for moving the measurement head, readings can be taken at various points on the product to be measured. The instrument's modular design enables targeted selection of the optimal X-ray source and the ideal detector to meet your specific requirements. https://youtu.be/2JyWAduAX9w -

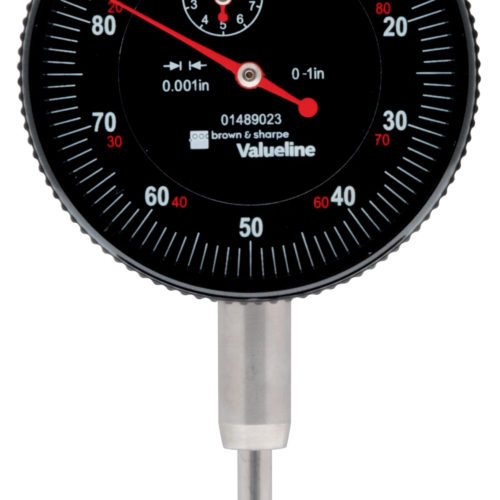

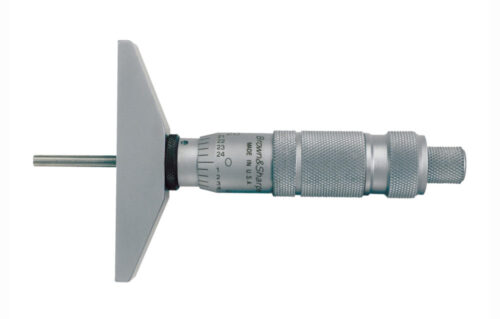

Micrometer Depth Gages are available in both inch and metric models. Both feature a hardened, precision base. Bases are available in lengths of 2.5" / 63.5 mm and 4" / 100 mm to satisfy a wide range of measuring applications. Base width is 1/2". All micrometer depth gages feature a satin-chrome finish for glare-free reading and a friction thimble for uniform measurements. All models on this page are supplied complete in a fitted mahogany case.

Micrometer Depth Gages are available in both inch and metric models. Both feature a hardened, precision base. Bases are available in lengths of 2.5" / 63.5 mm and 4" / 100 mm to satisfy a wide range of measuring applications. Base width is 1/2". All micrometer depth gages feature a satin-chrome finish for glare-free reading and a friction thimble for uniform measurements. All models on this page are supplied complete in a fitted mahogany case. -

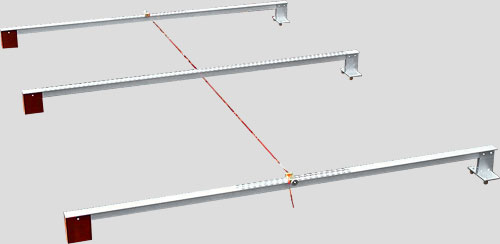

Arrow height measuring slats "Wuppertal method" The measuring slat set consists of 2 end slats (± 200 mm) and a middle slat with scale (± 700 mm). J Ede Endlatte has a displaceable tab, with which a desired value is set at consider endpoint. The tendon can then be inserted into the notch provided for this purpose. The measuring slats are made of aluminum T-profile and equipped with scratch-resistant scales of anodized pressure.

Arrow height measuring slats "Wuppertal method" The measuring slat set consists of 2 end slats (± 200 mm) and a middle slat with scale (± 700 mm). J Ede Endlatte has a displaceable tab, with which a desired value is set at consider endpoint. The tendon can then be inserted into the notch provided for this purpose. The measuring slats are made of aluminum T-profile and equipped with scratch-resistant scales of anodized pressure. -

Sighting and leveling device Regardless of leveling , longitudinal or track height determination, the VIG 1300 masters all tasks with the familiar precision and reliability of a Vogel & Plötscher measuring device. The technology and functionality of this measuring device have been continuously developed and optimally adapted to the requirements of the users.

-

Gauge template for rail seats on sleepers SML is based on a track gauge measurement device and used to measure the spacing of ribs at ribbed base-plates for rail seating on sleepers. The device is available in 2 designs with different effective ranges: SML 10: for measurements related to "inner ribs" SML 2: for measurements related to "outer ribs"

Gauge template for rail seats on sleepers SML is based on a track gauge measurement device and used to measure the spacing of ribs at ribbed base-plates for rail seating on sleepers. The device is available in 2 designs with different effective ranges: SML 10: for measurements related to "inner ribs" SML 2: for measurements related to "outer ribs" -

Rail head wear measuring device The measuring devices of the SKM series serve for the fast measurement of the wear on the rail head with Vignol rails - laterally as well as vertically. SKM 1 The driving edge measurement is carried out at 45 ° to the rail centerline. SKM 2 Here, the travel edge is measured at 22.5 °, 45 ° and 67.5 ° to the rail centerline.

Rail head wear measuring device The measuring devices of the SKM series serve for the fast measurement of the wear on the rail head with Vignol rails - laterally as well as vertically. SKM 1 The driving edge measurement is carried out at 45 ° to the rail centerline. SKM 2 Here, the travel edge is measured at 22.5 °, 45 ° and 67.5 ° to the rail centerline. -

Template for checking and adjusting of track and cant measuring devices The RV21 is used to check and adjust the accuracy of analogue and digital switch gauge and cant measuring devices. The template is made of special light-metal section tubes. The central base can be horizontally aligned by four adjuster screws. A traverse with hardened locators to check the respective measurement parameters is mounted on the base. The traverse is mounted on an articulated bearing on one side. This articulated joint, complete with a switching cam, is used to set the specified cants of 50, 100, 150 and 190 mm.

Template for checking and adjusting of track and cant measuring devices The RV21 is used to check and adjust the accuracy of analogue and digital switch gauge and cant measuring devices. The template is made of special light-metal section tubes. The central base can be horizontally aligned by four adjuster screws. A traverse with hardened locators to check the respective measurement parameters is mounted on the base. The traverse is mounted on an articulated bearing on one side. This articulated joint, complete with a switching cam, is used to set the specified cants of 50, 100, 150 and 190 mm. -

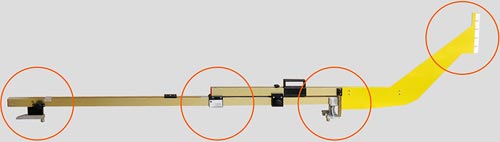

Mobile corrugation measuring system

Mobile corrugation measuring systemApproved measuring device according to DB and DIN EN 13231-3: 2012 for the acceptance of rail profile work Correct checking of the rail longitudinal profile, especially after reprofiling work such as rail grinding or milling, is of central importance. RMF 1100 fulfills these requirements as precisely as efficiently . Compared to its "big brother RMF 2.3E", the RMF 1100 is built more compact (shorter) and detects waves up to a maximum length of 1000 mm. The central feature is Vogel & Plötscher's specially developed and patented measuring principle - proven for years and internationally recognized. The scanning of the rail is effected touching by a special probe with high-resolution sensor (measuring interval = 2 mm). The decisive advantage: RMF 1100 thus maps the actual primary profile, ie it provides the real raw data of the rail surface! These are of particular importance since they represent a verifiable and therefore reliable basis for the assessments, for example according to DB guideline 824 or DIN EN 13231-3: 2012.

-

Determination of Rail Vehicle Quality [QKw] Re-profiling of rails leads to characteristic machining features on the rail surface . These features, depending on the nature and extent of different effects, especially on the noise in the track. The quality of the rail surface is thus of substantial importance and at the same time an objective yardstick. For the uniform evaluation of the rail driving surface a quality characteristic [QKw] was developed and introduced. The metrological determination of the quality characteristic value is demanding, since even the smallest irregularities below the typical Riffel wavelengths of 10-30 mm must be taken into account.

Determination of Rail Vehicle Quality [QKw] Re-profiling of rails leads to characteristic machining features on the rail surface . These features, depending on the nature and extent of different effects, especially on the noise in the track. The quality of the rail surface is thus of substantial importance and at the same time an objective yardstick. For the uniform evaluation of the rail driving surface a quality characteristic [QKw] was developed and introduced. The metrological determination of the quality characteristic value is demanding, since even the smallest irregularities below the typical Riffel wavelengths of 10-30 mm must be taken into account. -

Digital corrugation measuring system

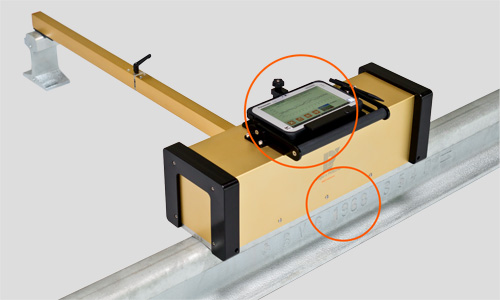

Digital corrugation measuring systemEverywhere, where rails are welded, ground and milled, the result for quality control can be measured: a case for the RM 1200 digital.

The recognized and handy measuring system is immediately ready for use, a measurement process completed within a few seconds. The latest generation of the proven RM 1200digital is equipped with a powerful outdoor tablet, the "MiniPad". In addition to a high-resolution 7 "color display, this offers comfortable touch-screen operation in a familiar Windows environment. The measured data are displayed graphically in real time and then stored on the MiniPad or evaluated directly. -

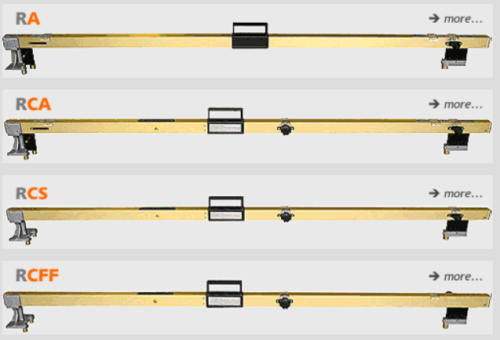

Analogue track gauge and switch measuring devices The well-known and proven R-series of track measuring devices, suitable for all standard track gauge and cant measurement applications. The R-series devices are designed in modular form and can be delivered for any gauge and with different additional equipment (see options).

Analogue track gauge and switch measuring devices The well-known and proven R-series of track measuring devices, suitable for all standard track gauge and cant measurement applications. The R-series devices are designed in modular form and can be delivered for any gauge and with different additional equipment (see options). -

PMS II is a particularly handy and efficient solution for the digital acquisition of the rail cross profile. Only a few steps and the measuring system is ready for use. Operation is menu-driven via the docked display and operating unit "MPCe". The measuring process is fully automatic and completed within 30 seconds. The measurement result is displayed immediately graphically and can then be stored on the internal SD card.

The detection of the rail profile is touching, ie with a high-precision sensor, the rail surface is scanned and transmitted the measurement data directly to the MPCe. The stored measurement files can then be transferred via SD card to an office computer. By means of the provided evaluation software "PMS-viewer" a detailed analysis of the measurement result is possible. Thus, one measurement can be directly compared with another or set in relation to a stored reference profile (target-actual comparison). Optionally, the functionality of the PMS II can be extended. With the help of an integrated laser measuring unit, additional data on the quantity removal or the groove depth can be determined. -

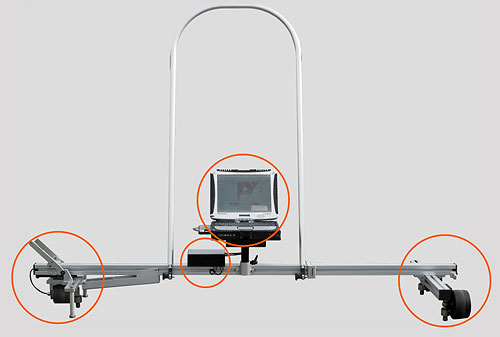

Continuous track measuring trolley MessReg CTS is a mobile digital measuring system for the measurement of track gauge, cant and twist. Thanks to its automatic continuous data capture it measures long track sections highly efficiently. The accessory "MPC" notebook enables users to enter comments during the measurement procedure, such as to document any irregularities or damage to the track specific to the exact position. Optionally, GPS data can be integrated, too. The measurement results are immediately available for local evaluation. The version MessReg CTS-T is equipped with integrated partition. Thus, the measuring device can be folded to very compact dimensions in three quick manual movements.

Continuous track measuring trolley MessReg CTS is a mobile digital measuring system for the measurement of track gauge, cant and twist. Thanks to its automatic continuous data capture it measures long track sections highly efficiently. The accessory "MPC" notebook enables users to enter comments during the measurement procedure, such as to document any irregularities or damage to the track specific to the exact position. Optionally, GPS data can be integrated, too. The measurement results are immediately available for local evaluation. The version MessReg CTS-T is equipped with integrated partition. Thus, the measuring device can be folded to very compact dimensions in three quick manual movements. -

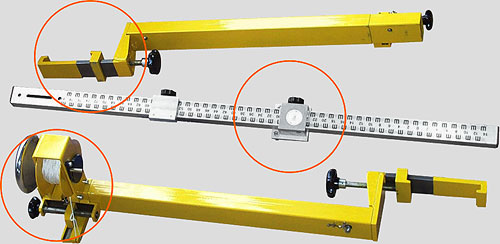

Digital track position measuring system

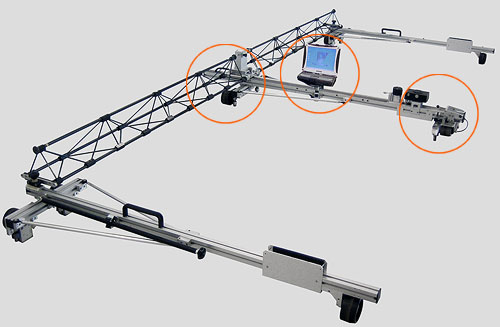

Digital track position measuring systemMessReg CLS impresses with its digital track position measurement based on a genuine 10m string. This chord length guarantees very accurate and reliable measurement data. The measurement result is thus particularly true to the track reality and is less the result of pure data extrapolation (as with instruments with short tendons).

MessReg CLS can be used very variably. The measuring tendon made of torsion-resistant carbon is modularly constructed from 5 segments á 2 m. In this way, besides the typical 6: 4 division, the measuring system can also be operated with other chord lengths and splits. Even the use without a string (then as a compact, wheeled track and cross height meter) is possible.

The measuring system automatically and continuously records all relevant track position parameters. These are displayed both graphically and numerically in real time and stored. In addition, the user can enter remarks on the track condition at any time and record them with exact position.

Thanks to its modular device design, MessReg CLS can be assembled / disassembled within a few minutes. Basically, just as for the measuring operation, a single person is sufficient.

-

Continuous track and switch measuring trolley Practical, intelligent and efficient - for digital track and switch inspection MessReg CDM is the benchmark! The globally tried and proven measuring system provides automatic continuous data capture with impressive levels of precision: Pre-defined measuring points are automatically detected and stored, and any tolerance infringements are colour-highlighted while the measurement is in progress. This means it takes just a few minutes to fully check a switch or a section of rail. Comments can be entered at any time, including indications of the track's condition at specific positions. The measurement report is evaluated and outputted in digital form immediately after the measurement procedure. Continuous measurement with MessReg CDM also provides comprehensive track documentation. Alongside the pre-defined measuring points, the track gauge and cant values are recorded automatically at 5 mm intervals. The measuring system is rounded off by an all-weather computer notebook running a powerful software package. The software includes the actual data capture program, graphical data display and evaluation programs, and professional track and switches management functionality. Note: MessReg CDM is the first and to date only continuously measuring switch inspection system approved by Deutsche Bahn.

Continuous track and switch measuring trolley Practical, intelligent and efficient - for digital track and switch inspection MessReg CDM is the benchmark! The globally tried and proven measuring system provides automatic continuous data capture with impressive levels of precision: Pre-defined measuring points are automatically detected and stored, and any tolerance infringements are colour-highlighted while the measurement is in progress. This means it takes just a few minutes to fully check a switch or a section of rail. Comments can be entered at any time, including indications of the track's condition at specific positions. The measurement report is evaluated and outputted in digital form immediately after the measurement procedure. Continuous measurement with MessReg CDM also provides comprehensive track documentation. Alongside the pre-defined measuring points, the track gauge and cant values are recorded automatically at 5 mm intervals. The measuring system is rounded off by an all-weather computer notebook running a powerful software package. The software includes the actual data capture program, graphical data display and evaluation programs, and professional track and switches management functionality. Note: MessReg CDM is the first and to date only continuously measuring switch inspection system approved by Deutsche Bahn. -

Digital center-piece measuring system Centerpieces in points are of particular importance, in particular with regard to track safety. Regular inspections and repair measures in the centerpiece area are therefore mandatory. Usually only punctual test equipment is available for this purpose. However, in order to be able to make objective statements about the qualitative overall condition of the heart and its lying time, a holistic measurement is necessary. This is exactly where the digital heart rate measuring device (HMG) comes into its own. The HMG determines the complete overflow geometry of turnout frog pieces in relation to a specified target profile. In addition, the flow geometry of the frog point is recorded. On the basis of the measurement data, not only the overall condition can be assessed, but also the quality of completed repair measures (eg build-up welding, reprofiling, centerpiece replacement, etc.) can be documented.

Digital center-piece measuring system Centerpieces in points are of particular importance, in particular with regard to track safety. Regular inspections and repair measures in the centerpiece area are therefore mandatory. Usually only punctual test equipment is available for this purpose. However, in order to be able to make objective statements about the qualitative overall condition of the heart and its lying time, a holistic measurement is necessary. This is exactly where the digital heart rate measuring device (HMG) comes into its own. The HMG determines the complete overflow geometry of turnout frog pieces in relation to a specified target profile. In addition, the flow geometry of the frog point is recorded. On the basis of the measurement data, not only the overall condition can be assessed, but also the quality of completed repair measures (eg build-up welding, reprofiling, centerpiece replacement, etc.) can be documented.